The hydrogen industry is in a period of significant change. Traditional hydrogen production methods, primarily reliant on fossil fuels, are gradually declining. In contrast, there's a rapid increase in the production of green hydrogen, typically generated through electrolysis. This shift, however, raises concerns about the impact on water resources, especially as many green hydrogen projects are located in regions already facing water scarcity.

Water is essential in the energy sector, a relationship known as the water-energy nexus. This interdependence is also evident in the hydrogen economy, underscoring the need for stakeholders to consider the implications of increased hydrogen production, particularly green hydrogen, on water resources.

Water Requirements in Hydrogen Production

Currently, the predominant method of hydrogen production is steam methane reforming (SMR). This process, which generates grey or blue hydrogen (the latter when combined with carbon capture and sequestration), requires about 4.5kg of water per kg of hydrogen. Electrolysis, an emerging alternative, splits water into hydrogen and oxygen using electricity and needs about 9kg of water per kg of hydrogen, double the amount required for SMR. However, in both processes, a significant portion of water is used for cooling, with some being discharged back into the environment or lost through evaporation.

The total water requirement varies depending on several factors, including the quality of water and treatment methods. Estimates of water impact vary, with figures ranging from 9-24kg (according to Bluefield) to 1210kg (GWI estimate with desalination) per kg of hydrogen. Generally, about 60-95kg of water is needed per kg of hydrogen, predominantly for cooling purposes.

The Electrolysis Process and Water Usage

Electrolysis plants, critical in green hydrogen production, require a steady supply of high-quality water for both feedstock and cooling. This water can come from municipal sources or alternative sources such as freshwater, brackish water, or seawater. Opportunities exist for projects to utilize recycled water, for example, by situating near wastewater treatment facilities.

The water used in electrolyzers must be ultrapure, undergoing reverse osmosis (RO) and deionization. Unfortunately, a significant portion (over 20%) of this water is rejected as wastewater. A part of the RO-treated water is diverted for cooling, which is recirculated and eventually returned to the environment.

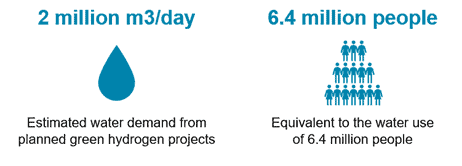

Planned Hydrogen Projects and Water Stress

Research by Bluefield indicates that 85% of planned hydrogen projects are in water-stressed areas, with about 40% planning to use desalinated seawater. While desalination can alleviate local water stress, it is often a costly option, contributing to the higher price of green hydrogen compared to grey and blue hydrogen.

Conclusion

The development of the green hydrogen sector necessitates a clearer understanding and transparency regarding its water usage and impact on local water resources. The conversation about green hydrogen serves as a reminder that reducing emissions does not always correlate with lower water consumption. Solutions must be evaluated holistically, considering their overall climate impact.

In this evolving landscape, hydrogen water machines, hydrogen water bottles, hydrogen water generators, and the associated benefits are becoming increasingly relevant. These technologies not only represent advancements in hydrogen utilization but also play a role in the broader discussion of sustainable hydrogen production and its environmental implications